What does the thermal expansion coefficient of PCB board mean? How was it measured?

The thermal expansion coefficient of the PCB board refers to the change in the length of the material per unit length under unit temperature change when the temperature of the material changes. Simply put, it is the proportion of length change caused by temperature changes when a material is heated or cooled.

The thermal expansion coefficient is a material physical property parameter used to describe the behavior of materials during thermal expansion and contraction. It can affect the dimensional accuracy and performance stability of materials. Especially for electronic devices, accurate understanding and control of the thermal expansion coefficient is crucial to ensure product quality and reliability.

The coefficient of thermal expansion is usually expressed in ppm/°C (parts per million per degree Celsius). For example, assuming a material has a thermal expansion coefficient of 20 ppm/°C, the length of the material will increase by 0.002% of the original length for every 1°C increase in temperature.

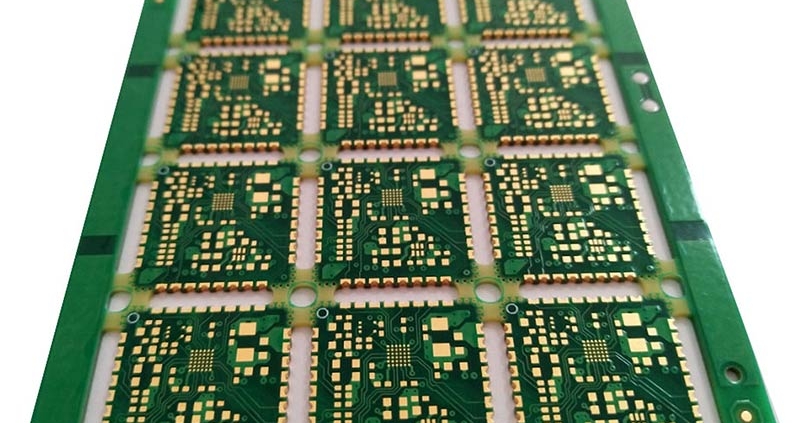

PCB board is a common electronic component substrate and is widely used in the fields of electronics and communications. Electronic devices generate heat during operation, and thermal expansion and contraction are very common. Therefore, it is very important to select the appropriate PCB board material and accurately measure its thermal expansion coefficient.

There are many methods to measure the thermal expansion coefficient of PCB boards. Two common measurement methods will be introduced below.

1. Expanded cantilever beam method

The expansion cantilever beam method is an indirect method of measuring the thermal expansion coefficient and is often used for small sample testing of PCB board materials. The principle is to calculate the thermal expansion coefficient by measuring the deflection of the material under temperature changes.

The specific experimental steps are as follows:

(1) Prepare a thin slice sample of appropriate size and fix it on the support beam to form a cantilever.

(2) Place the cantilever in a constant temperature environment and record the baseline deflection.

(3) Gradually heat or cool the cantilever and record the deflection at different temperatures.

(4) Use Hooks’ law to calculate the thermal expansion coefficient based on the deflection changes at different temperatures.

The advantage of this method is that the testing process is relatively simple and the equipment requirements are low. However, measurement accuracy may be limited because of the small sample size.

2. Thermal expansion coefficient meter method

The thermal expansion coefficient meter method is a method of directly measuring the thermal expansion coefficient and is suitable for testing large-size PCB board materials. This method calculates the thermal expansion coefficient by accurately measuring the linear expansion of materials at different temperatures.

The specific experimental steps are as follows:

(1) Prepare PCB board samples of suitable size.

(2) Fix the sample in the thermal expansion coefficient meter and establish the zero position of the measuring instrument.

(3) Adjust the temperature and record the sample length at different temperatures.

(4) Calculate the thermal expansion coefficient based on the recorded length changes.

The advantage of this method is that the test accuracy is relatively high and the thermal expansion coefficient of large-size samples can be accurately measured. However, the instruments and equipment are relatively expensive, and the testing process requires operators to have a certain technical level.

In addition to the above common measurement methods, there are other methods such as cantilever beam method, thermal difference method and expansion volume method. Each method has its applicable scope and advantages, and the choice should be based on actual needs.

To sum up, the thermal expansion coefficient of PCB board refers to the proportion of material length change per unit length under unit temperature change. Accurate measurement of thermal expansion coefficient is very important to ensure the quality and reliability of electronic devices. Common measurement methods include the expansion cantilever beam method and the thermal expansion coefficient meter method. Each method has its advantages and disadvantages and needs to be selected according to the actual situation.