What are PCB, PCBA, SMT and DIP?

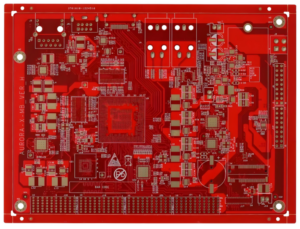

1. PCB (Printed Circuit Board): Printed Circuit Board

PCB is like the “blood vessels and skeleton” of electronic devices. Imagine that electronic devices are like a city, current is the “resource” flowing in the city, and PCB is the roads that transport “resources” and the framework that supports the city structure.

PCB is made by printing conductive lines and patterns on an insulating substrate. These conductive lines connect various electronic components, allowing current to flow smoothly in the circuit, thereby realizing various electronic functions.

For example, our common computer motherboard is a kind of PCB. There are densely packed lines and various jacks on the motherboard, which are used to connect electronic components such as CPU, memory, and graphics cards. Engineers will carefully design the layout and line direction of PCB according to the functional requirements of the computer. Just like urban planners design the layout of roads and buildings in the city, they have to consider how to make the connection between various components the most reasonable and efficient. Then, through plate making, etching and other processes, the designed pattern is turned into an actual PCB.

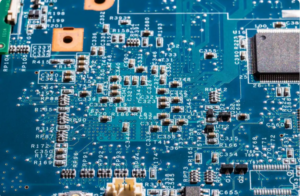

2. PCBA (Printed Circuit Board Assembly): Printed Circuit Board Assembly

PCBA is the process and result of installing and soldering electronic components to the circuit board based on the PCB. Simply put, PCBA is a PCB that has been installed with electronic components, just like a city that installs various buildings (electronic components) in the corresponding positions after building roads and frames.

During the PCBA process, various electronic components such as resistors, capacitors, chips, etc. need to be accurately placed in the designated positions on the PCB, and then firmly connected to the circuit board through welding and other methods. This is like when building a house, bricks, wood, steel beams and other materials must be accurately placed in the right position and fixed so that the house can be stable.

For example, the circuit board inside the smartphone in our hands is completed through the PCBA process. Various tiny electronic components are accurately installed on the PCB, and then a complete circuit system is formed through welding, so that the mobile phone can realize various functions such as calling, taking pictures, and surfing the Internet.

3. SMT (Surface Mount Technology): Surface Mount Technology

SMT is a commonly used installation technology in PCBA. It is like putting a “tight-fitting piece of clothing” on the PCB, and directly mounting the surface mount components with no pins or short pins on the surface of the PCB.

Compared with traditional plug-in technology, SMT has many advantages. It can make electronic products smaller, lighter and more compact. Just like the current smartphones, the reason why they can be made so light and thin is due to SMT technology. Through SMT technology, more components can be installed in a smaller space, greatly improving the integration and performance of the circuit.

For example, the chip in the mobile phone is installed on the PCB through SMT technology. The chip mounter is like a very precise “manipulator”. It can accurately place the tiny chip on the PCB, and then through the reflow process, the solder paste is melted at high temperature, and the pins of the chip are connected to the pads on the PCB to form a strong electrical connection. In this way, the mobile phone can realize various complex functions.

4. DIP (Dual In-line Package): Dual In-line Package

DIP is a packaging method for electronic components. Imagine that a DIP packaged electronic component is like a small box with two rows of “feet” that extend from both sides of the component to form two rows of parallel pins.

During the PCBA process, DIP components can be installed on the PCB by plug-in. Just like inserting a small box with feet into a board with holes, and then soldering it through processes such as wave soldering.

For example, some old-fashioned radios or simple electronic toys may use DIP packaged electronic components. Although these components are relatively large in size, they are low in cost. For some products with low cost requirements and low volume requirements, DIP packaged components are still a good choice.

In short, PCB is the carrier of electronic circuits, PCBA is the circuit board that completes component assembly, and SMT and DIP are two different electronic component installation technologies. They work together to form an important link in electronic manufacturing, bringing us a variety of powerful electronic devices.