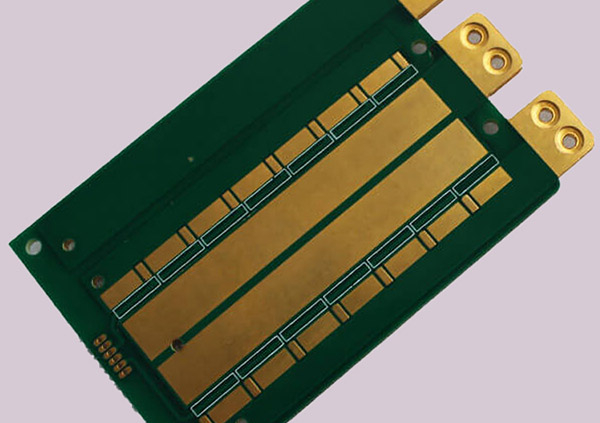

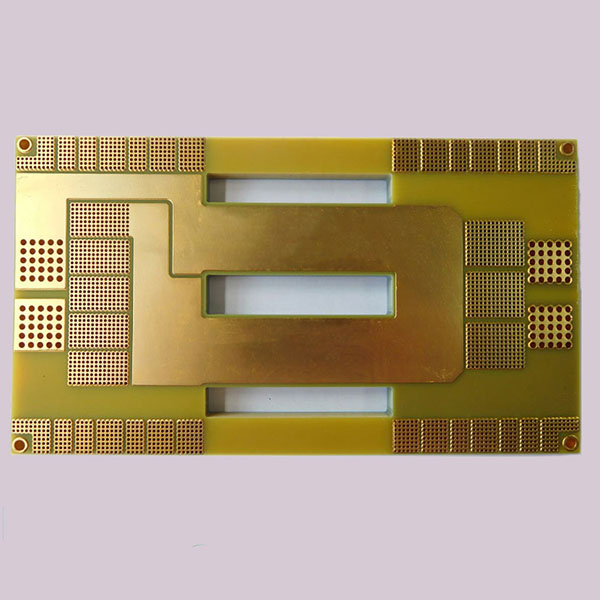

What fields are thick copper PCB used in? Unlock the multi-faceted identity of thick copper PCB!

In recent years, with the rapid development of science and technology, the application scope of PCB (Printed Circuit Board) thick copper plates has gradually expanded, and it has shown an amazing multi-faceted identity in various fields. This article will focus on the PCB thick copper plate and explore its wide range of applications in the electronic field.

1. Power electronics applications

PCB thick copper plate plays a vital role in the field of power electronics. In high-power equipment such as power amplifiers, inverters, and rectifiers, the use of PCB thick copper plates can effectively improve heat dissipation performance and ensure stable operation of the equipment under high loads. Due to its excellent heat dissipation characteristics, PCB thick copper plates are widely used in various industrial power supplies, UPS, transformers and other equipment. In power electronic equipment, PCB thick copper plates can not only provide good heat dissipation effects, but also increase current carrying capacity, reduce resistance and losses, and improve equipment performance and reliability. Therefore, PCB thick copper plate has become one of the indispensable key materials in the power electronics industry.

2. Automotive electronics field

With the rapid development of automotive electronics technology, PCB thick copper plates have also shown strong application potential in the field of automotive electronics. In fields such as electric vehicles, smart driving, and in-vehicle entertainment systems, PCB thick copper plates can provide stable and reliable electrical connections to meet the needs of high-power and high-frequency electronic equipment. In addition, automotive electronic equipment often needs to work in harsh working environments, such as high temperature, high humidity, vibration and other conditions. The high strength, high reliability and stable performance of PCB thick copper plate make it an ideal choice in the automotive electronics industry.

3. Communication equipment applications

In the field of communication equipment, such as base stations, satellite communications, wireless networks and other equipment, PCB thick copper plates also play a key role. Since communication equipment needs to carry high-power, high-frequency signals, the low resistance, high thermal conductivity and stable performance of PCB thick copper plates make them popular in this field. PCB thick copper plates can not only improve the stability and speed of signal transmission in communication equipment, but also reduce the size of the circuit board and improve the integration and performance of the equipment. Therefore, communication equipment manufacturers are increasingly inclined to use PCB thick copper plates to meet the demand for high-power, high-frequency equipment.

4. Aerospace applications

In the aerospace field, the requirements for electronic equipment are more stringent, and the application of PCB thick copper plates is also more prominent. Aerospace equipment needs to have the characteristics of lightweight, high reliability and high temperature resistance, and PCB thick copper plate can meet these needs. PCB thick copper plates can withstand the working environment under harsh conditions such as high temperature, high pressure and strong vibration in aerospace equipment, ensuring the normal operation of electronic equipment. At the same time, PCB thick copper plates can also meet the needs of aerospace equipment for high-power and high-frequency electronic devices, ensuring equipment performance and safety.

PCB thick copper plates are widely used in power electronics, automotive electronics, communication equipment, aerospace and other fields. Its excellent heat dissipation performance, high current carrying capacity and stable performance make it an indispensable and key component in the modern electronics industry. With the continuous advancement of technology and the expansion of application fields, PCB thick copper plates will continue to play an important role in promoting the development and innovation of electronic equipment.