The role of using three proof paint in PCBA processing.

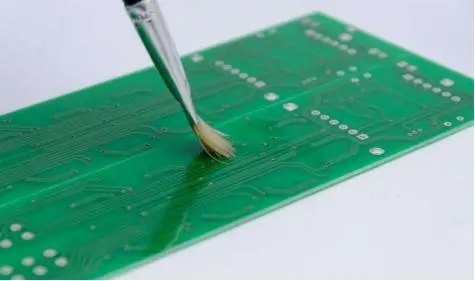

As one of the key links in the electronic product manufacturing industry, PCBA processing has an importance that cannot be ignored in the modern industrial field. In the PCBA processing process, the use of conformal anti-paint with its unique characteristics can not only effectively protect the circuit board from damage caused by water immersion, pollution and other factors, but also improve the reliability and stability of electronic products. . Next, we will delve into the role of conformal paint in PCBA processing and introduce in detail its importance in protecting circuit boards from water, dust and corrosion.

1. Protect the circuit board from water

Water resistance is a crucial consideration in the manufacturing process of electronic products. Since the circuit board contains many precision electronic components, the penetration of moisture will cause short circuits, insulation failure and other problems on the circuit board, which will seriously affect the normal operation of the product. The conformal anti-paint used in PCBA processing was introduced to solve this problem. The conformal anti-paint has good waterproof performance and can effectively isolate the erosion of external moisture and protect the circuit board from the threat of moisture.

2. Protect circuit boards from dust

In addition to waterproofing, dustproofing is also an important aspect to consider during PCBA processing. The tiny size and high sensitivity of electronic components make them extremely susceptible to contamination by dust and impurities. These contaminants can affect the normal operation of the circuit board and even cause circuit short circuits. Therefore, the use of conformal paint during PCBA processing can effectively isolate the circuit board from dust and protect the normal operation of electronic components.

3. Protect circuit boards from corrosion

In addition to being waterproof and dustproof, the conformal paint used in PCBA processing also has anti-corrosion functions. During the manufacturing and use of electronic products, circuit boards are easily susceptible to corrosion and failure due to the presence of oxygen, moisture, chemicals and other factors. The use of conformal paint can provide a protective film for circuit boards, effectively isolate external corrosion factors and extend the service life of electronic products.

In summary, the use of conformal paint in PCBA processing plays an irreplaceable and important role in protecting circuit boards from water, dust and corrosion. By using conformal coating, it can not only enhance the water, dust and corrosion resistance of electronic products and extend their service life, but also improve the reliability and stability of the product. Therefore, in the PCBA processing process, the rational use of conformal paint is a necessary means to ensure the quality and performance of electronic products.