Strong power is the key to victory! Circuit board thick copper board manufacturer helps you achieve technological breakthroughs!

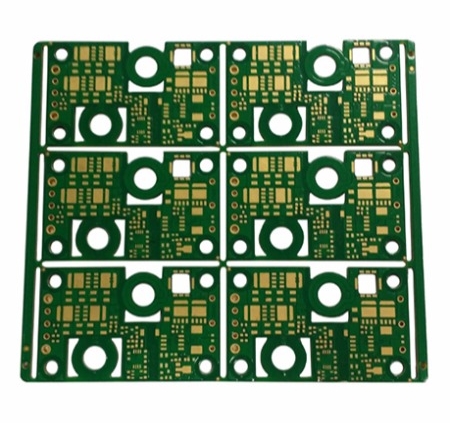

Circuit board thick copper board is an indispensable key component in electronic equipment. It provides stable electrical connection and good thermal conductivity, providing strong power for the normal operation of the equipment. This article will elaborate on the thick copper board of circuit board from the following four aspects, including material properties, manufacturing process, application fields and future development trends.

1. Material properties

Thick copper boards have excellent electrical conductivity and thermal conductivity. Compared with ordinary circuit boards, thick copper boards have higher current carrying capacity and lower line impedance, and can meet the needs of high-frequency and high-power equipment. In addition, thick copper plates also have good corrosion resistance and mechanical strength, and can operate stably in various harsh environments.

2. Manufacturing process

The manufacturing process of thick copper boards is relatively complex and requires multiple processes. The first is material selection and cutting. Select copper plates with high purity and fine crystallization as raw materials, and use precision cutting equipment to cut them into the required shape. Then comes surface treatment, including chemical cleaning and anti-oxidation treatment to ensure the purity and stability of the circuit board surface. Next comes pattern drawing and copper lamination, using photolithography technology for image transfer, and laminating the copper foil to the substrate through high temperature and high pressure. Finally, there are processes such as drilling, lead-tin plating, printing and testing to complete the manufacturing of the entire circuit board.

3. Application fields

Thick copper boards are widely used in various high-power and high-frequency electronic equipment, including communication equipment, computer equipment, power supply equipment, automotive electronics, etc. In communication equipment, thick copper plates are used to make high-frequency radio frequency modules and antennas; in computer equipment, thick copper plates are used to make high-performance CPU radiators and cooling modules; in power supply equipment, thick copper plates are used to make high-performance Current DC bus and current sampling resistor, etc. Due to its excellent performance, thick copper boards are also widely used in fields such as new energy vehicles and aerospace.

4. Future development trends

With the continuous development and upgrading of electronic equipment, the requirements for circuit boards are becoming higher and higher. In the future, circuit board thick copper boards will continue to develop towards high density, high performance and multi-function. For example, multi-layer stacking technology and new materials are used to achieve a more compact design and higher circuit integration; advanced heat dissipation technology is used to improve heat dissipation efficiency and meet the thermal management needs of new generation equipment; flexible circuit technology is used to achieve Bending and folding expand the application scenarios of circuit boards. To sum up, circuit board thick copper plate is the key to success in electronic equipment and will help technology achieve new breakthroughs in continuous innovation and development.

As a key component in electronic equipment, circuit board thick copper boards have excellent material properties and manufacturing processes. It is widely used in many fields and provides strong power for the normal operation of equipment. With the continuous development and advancement of electronic equipment, thick copper boards will continue to develop in terms of high density, high performance and multi-function, helping to achieve technological breakthroughs. It is believed that circuit board thick copper board manufacturers will continue to provide innovative products and services to meet market demand and promote the development of the electronics industry.