Special PCB board material product display

At present, most PCB substrates are made of FR-4 glass fiber substrate. This material has good insulation, corrosion resistance, high temperature resistance, and high cost performance, so most PCBs use this as the substrate.

However, for some products with specific electrical performance requirements, the performance of conventional substrates is not enough. These special properties require the use of some special substrates to meet them. Today, we will introduce some common special substrate products.

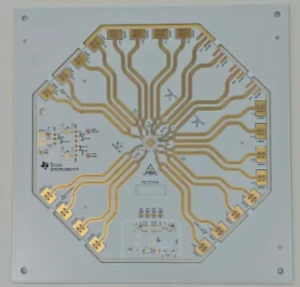

TUC 872LK

The above is an 8-layer HDI PCB of TUC872. TUC872 is a high-speed special board that we often use. It has a low dielectric constant, which is conducive to the transmission of high-speed signals. It also has a low dielectric loss factor, which means low energy loss during signal transmission, ensuring the strength of signal transmission!

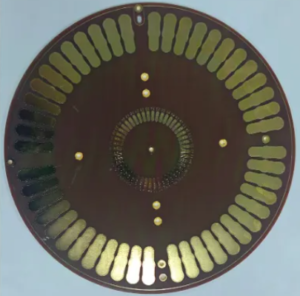

VT-901

This pancake-like PCB is made of VT-901 polyimide material. The ultra-high strength board performance enables the product to adapt to most harsh environments. Whether it is high temperature and high pressure, or low temperature and low pressure, it can perform its due functions well!

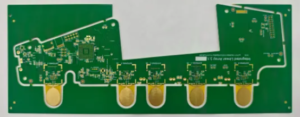

Rogers 4003C

RO4003 is a material with a hydrocarbon resin system and ceramic filler reinforced with woven glass cloth, and its electrical properties are close to those of PTFE/woven glass cloth materials. It is an excellent high-frequency PCB substrate with a stable dielectric constant. It can ensure the stability and accuracy of signal transmission in high-frequency circuits, and give the circuit good impedance control. It is widely used in microstrip line design, cellular base station antennas, point-to-point microwave communications, etc., and can ensure high-speed data transmission and stable signal coverage. For example, in the construction of 5G communication base stations, RO4003C can be used to make PCBs for base station antennas to meet the transmission requirements of 5G high-frequency signals.