Revealing the difference between high-frequency PCB and ordinary PCB, do you really understand it?

In the electronics industry, PCB (Printed Circuit Board) is an important component, which carries electronic components and provides connection functions. In the world of PCB, high-frequency PCB and ordinary PCB are two common concepts. However, do you really know the difference between them? This article will reveal the differences between high-frequency PCBs and ordinary PCBs to help you understand them better.

Material selection: High-frequency PCB requires the use of special materials with low dielectric constant and low loss tangent to support higher frequency signal transmission and faster data processing. Ordinary PCBs may use conventional FR-4 materials or other more common materials.

Hierarchical structure: High-frequency PCBs may adopt more hierarchical structures to achieve complex signal stacking and impedance matching. In comparison, a normal PCB may require less hierarchical structure.

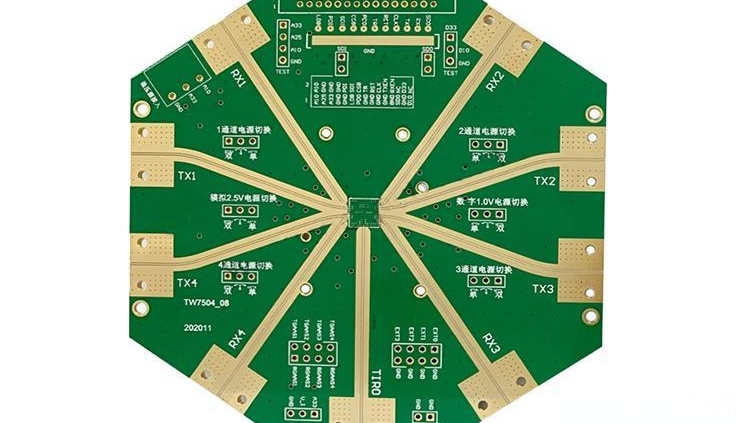

Layout and wiring: The layout and wiring of high-frequency PCBs need to be more precise and rigorous to minimize signal path length, signal distortion and crosstalk. The layout and wiring of ordinary PCB may be relatively more flexible and simple.

Impedance control: High-frequency PCBs need to strictly control the impedance matching of signal transmission lines to ensure stable signal transmission. In comparison, ordinary PCBs may have less stringent requirements for impedance control.

Testing requirements: The testing requirements for high-frequency PCBs are more stringent, and more advanced testing equipment and technologies are usually required to ensure the accuracy and stability of signal transmission. The testing requirements for ordinary PCBs may be relatively simple and straightforward.

Cost and manufacturing process: Because high-frequency PCBs have higher requirements on materials, processes, and testing, manufacturing costs may be higher. The manufacturing cost of ordinary PCB is relatively low, and the manufacturing process is relatively simple.

In general, there are some differences between high-frequency PCBs and ordinary PCBs in terms of material selection, hierarchical structure, layout and wiring, impedance control, testing requirements and manufacturing costs. High-frequency PCBs are more specialized and complex and are suitable for application scenarios with higher signal transmission requirements, while ordinary PCBs are more versatile and suitable for general electronic product manufacturing. By understanding these differences, it helps us better select and apply suitable PCBs and improve the performance and stability of electronic equipment.