Optimize PCB production line control specifications to reduce production costs and risks!

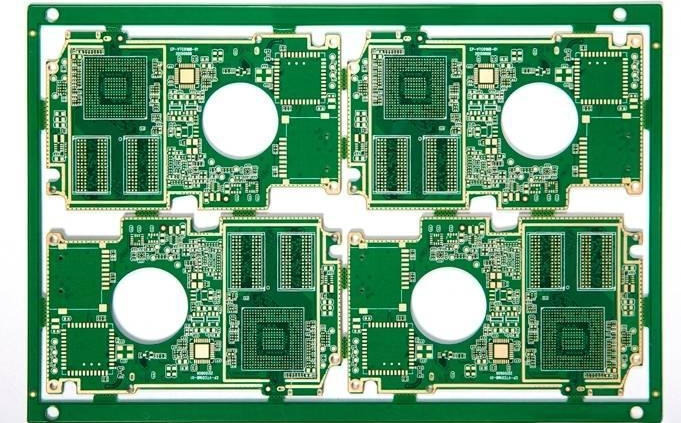

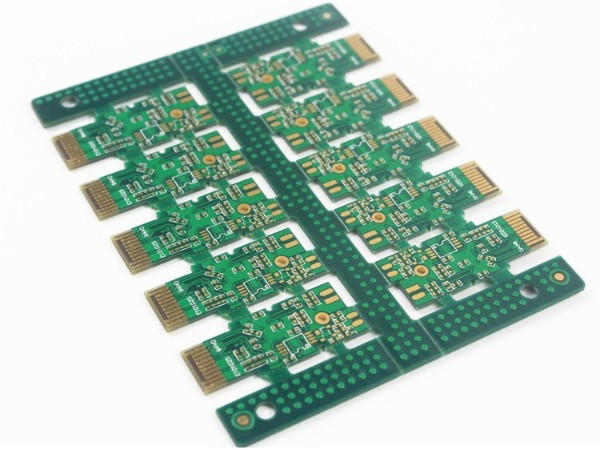

In today’s rapidly developing electronic manufacturing industry, printed circuit boards (PCBs) are an indispensable core component of electronic products, and their production efficiency and cost control directly determine the market competitiveness of enterprises. With the continuous advancement of technology and the continuous changes in the market, optimizing the control specifications of PCB production lines and reducing production costs and risks have become urgent issues for enterprises to solve.

First of all, we need to clarify the importance of PCB production line control specifications. PCB production line control specifications are key factors to ensure the smooth progress of the production process, stable product quality, and controllable costs. A reasonable control specification can not only improve production efficiency and reduce resource waste, but also reduce potential risks in the production process and ensure the sustainable development of the enterprise.

However, in the actual production process, PCB production lines often face many challenges. Such as complex process flow, a wide variety of equipment, and uneven operating levels of personnel, all of which bring great difficulties to production line control. Therefore, it is imperative to optimize the control specifications of PCB production lines.

To optimize the control specifications of PCB production lines, it is first necessary to conduct a comprehensive assessment of the existing production lines. By in-depth understanding of the process flow, equipment conditions, staffing, and other aspects of the production line, find out the existing problems and bottlenecks. At the same time, combined with market demand and technological development trends, formulate practical optimization plans.

In the optimization process, we can start from the following aspects:

Introduce advanced production management system. By introducing advanced production management system, we can realize real-time monitoring and data analysis of the production process, improve production efficiency and product quality. At the same time, the system can also provide early warning and prediction functions to help enterprises discover and solve potential problems in advance.

Optimize process flow. Sort out and optimize each link of PCB production to reduce unnecessary processes and waste. By introducing automated equipment, improve the automation level of the production line and reduce the impact of human factors on production. At the same time, strengthen the monitoring and adjustment of process parameters to ensure the consistency and stability of product quality.

Strengthen equipment management and maintenance. Regularly inspect and maintain production equipment to ensure the normal operation of equipment. At the same time, introduce equipment preventive maintenance strategies to reduce equipment failure rate and improve the stability and reliability of the production line.

Through the implementation of the above measures, we can effectively optimize the control specifications of PCB production lines and reduce production costs and risks. This will not only help enhance the market competitiveness of enterprises, but also bring greater economic and social benefits to enterprises.