Optical Chip Carrier PCB

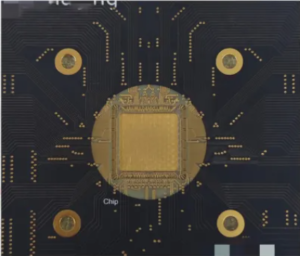

As science and technology develop, people’s observation of things is getting deeper and deeper. The product we bring today is an optical chip carrier used in single-photon SPAD imaging detectors. SPAD plays an important role in many fields, including but not limited to astronomy, particle size determination, quantum computing, quantum key distribution, single molecule detection, etc.

Regarding SPAD, interested friends can check the relevant information. Today, we mainly introduce this optical chip carrier PCB.

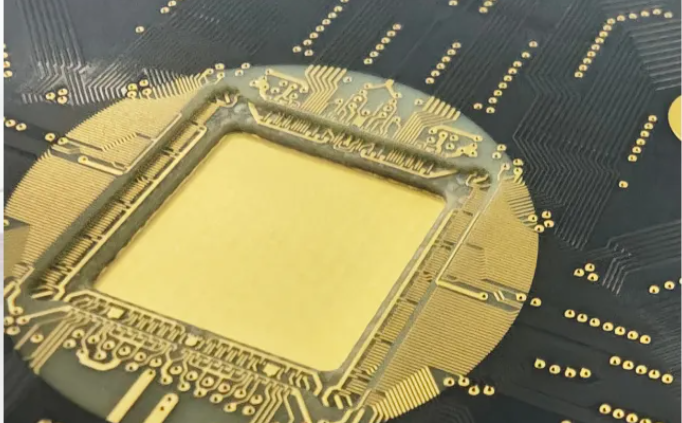

The most difficult part of the product process is these two steps, which require two depth control gongs and laser lid opening, and the depth control requirements are very strict.

The surface treatment adopts the ENEPIG process. The ENEPIG has strong adhesion and is not easy to fall off, which improves the reliability and stability of the product.

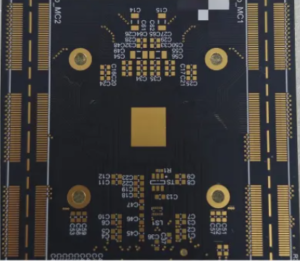

In addition, as a carrier board, the circuit design of the product is high-precision and highly integrated. The line width and line spacing are designed to be only 2mil. The minimum binding pad is 0.070mm.

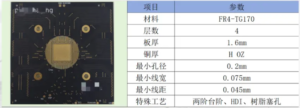

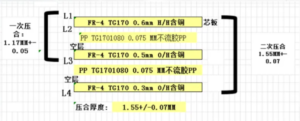

Although our product is only a 4-layer PCB, it needs to be pressed twice because of the steps. The following is the pressing structure diagram

PCB carrier is a special printed circuit board used to carry electronic components, with the characteristics of high precision, high reliability and high integration. It has excellent electrical, mechanical and thermal properties, and can meet the high performance requirements of various complex electronic systems. Its process is not as complicated as imagined, but the parameter requirements at the detail level are very strict!