Efficient energy management leads new trends, full analysis of new energy vehicle PCB applications!

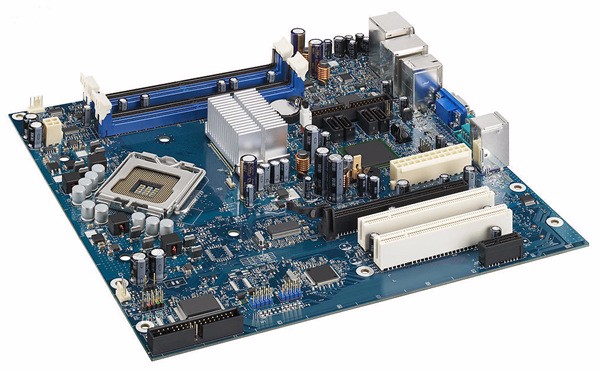

With the increasing global emphasis on environmental protection, new energy vehicles are gradually becoming the mainstream of the automotive industry. In the development of new energy vehicles, efficient energy management is a key link. In new energy vehicles, the application of PCB (Printed Circuit Board) plays a vital role. This article will provide a detailed analysis of new energy vehicle PCB applications from four aspects.

1. Development of new energy vehicle PCB technology

The development of new energy vehicle PCB technology is the basis for achieving efficient energy management. With the promotion of new energy vehicles and the increase in demand, traditional PCB technology can no longer meet the demand for efficient energy management. Therefore, new energy vehicle PCB technology continues to develop to achieve higher energy efficiency and reliability. For example, the application of high-density, multi-layer, and multi-function PCBs can make the wiring of vehicle electronic systems more compact, improve energy conversion efficiency, and provide more possibilities for function expansion.

2. Application of new energy vehicle PCB in battery management system

The battery is one of the core components of new energy vehicles, and the battery management system (BMS) is the key to its effective management. The application of new energy vehicle PCB in BMS can realize battery monitoring, charge and discharge control, temperature management and other functions. Through reasonable design and layout of PCB, the accuracy and stability of BMS can be improved, thereby extending the service life of the battery and improving energy utilization.

3. Application of new energy vehicle PCB in power system

The power system of new energy vehicles is the core component for energy conversion and transmission. In the power system, the application of new energy vehicle PCB can realize functions such as motor drive control, energy conversion between the battery and the motor, and linkage with other systems. Because new energy vehicle PCBs have reliability and stability in special environments such as high temperature and high current, they can improve the efficiency and safety of the power system.

4. Application of new energy vehicle PCB in intelligent systems

Intelligent systems are another important component of new energy vehicles, including car networking, autonomous driving and other functions. The application of new energy vehicle PCB in intelligent systems can realize the collection, processing and transmission of sensor data, and realize intelligent control and optimization of vehicles. Through the high integration and reliability of PCB, it is possible to realize the collaborative work of multiple systems and provide a safer, more efficient and intelligent driving experience.

The application of new energy vehicle PCBs is leading a new trend in efficient energy management. Through the technological development of PCB, the battery management system, power system and intelligent system of new energy vehicles have been greatly improved and optimized. The application of new energy vehicle PCB not only improves energy utilization and vehicle performance, but also enhances vehicle safety and reliability. With the further development of the new energy vehicle market, new energy vehicle PCB technology will continue to innovate and make greater contributions to the efficient energy management of new energy vehicles.