How to use high-speed PCB prototyping to improve product performance?

In the rapid development of modern electronic products, high-speed PCB proofing has become a key part of improving product performance. This article will introduce to you how to improve product performance through high-speed PCB proofing.

1. Understand the concept and significance of high-speed pcb prototyping

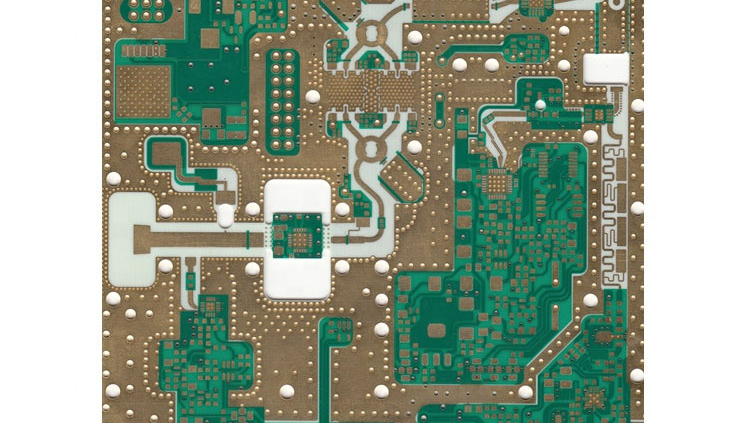

In electronic product design, high-speed PCB prototyping refers to the use of high-performance materials, precision processes and advanced equipment when designing and manufacturing PCB boards to meet high-speed signal transmission, anti-interference ability and stability requirements. Through high-speed PCB prototyping, signal transmission delay and signal distortion can be effectively reduced, and the reliability and stability of the product can be improved.

2. Choose suitable high-speed PCB materials

Choosing suitable high-speed PCB materials is an important step to ensure product performance improvement. Common high-speed PCB materials include FR-4, Rogers, PTFE, etc. According to the specific needs of the product, the dielectric constant, loss factor and thermal stability of the material are selected to meet the requirements of high-speed signal transmission.

3. Optimize PCB layout and routing

When performing high-speed PCB prototyping, reasonable layout and wiring design can significantly improve product performance. Try to shorten the signal transmission path as much as possible to reduce signal loss; avoid excessive plane layering to reduce signal crosstalk and interference. In addition, the ground wire and power wire should be properly set up to provide good ground potential and power supply stability.

4. Pay attention to the details in high-speed PCB proofing

When performing high-speed PCB prototyping, you also need to pay attention to some details to ensure the improvement of product performance. Choose the appropriate PCB manufacturer to ensure that it has advanced production equipment and rich experience; conduct strict process control, including controlling the accuracy of parameters such as board thickness, line width, line spacing; and conduct necessary testing and verification to ensure that the product The quality and performance meet expectations.

Using high-speed PCB proofing can significantly improve product performance, thereby achieving better user experience and market competitiveness. By choosing the right materials, optimizing layout and trace design, and paying attention to detail and process control, you can maximize product performance.