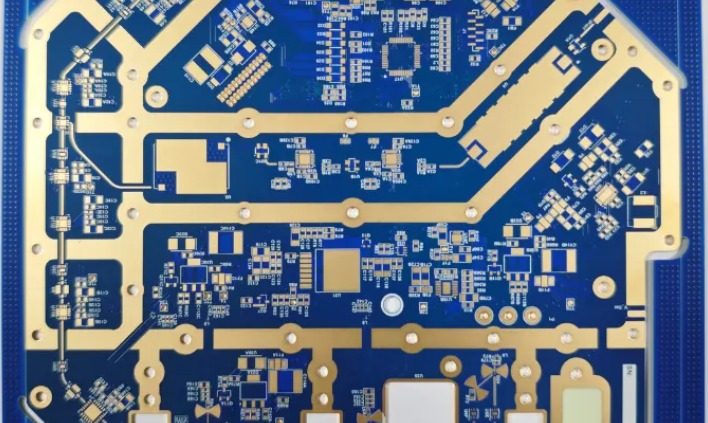

High frequency mixed pressing Copper paste plugging Deep groove control Metal edging PCB

With the rapid development of electronic technology today, PCB is the core component of electronic equipment, and its performance directly affects the quality and reliability of the entire electronic equipment. Most of the PCB products we usually see are made of a single core material, which is fine for conventional PCBs, but for some high-frequency and high-speed PCB products, the board value is relatively high. Mixing can save material costs. What we bring today is a Rogers 4003+IT180A mixed high-frequency PCB.

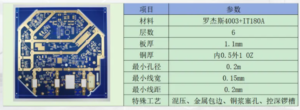

This product has a 6-layer PCB, L1-2 is high-frequency Rogers material, and L3-6 is conventional IT180 glass fiber material. This lamination structure saves material costs to a great extent while retaining the high-frequency performance of the product. However, mixed pressing is also a test of lamination technology. Core boards of different materials are prone to delamination during lamination, or layer deviation due to different expansion and contraction of the board. The lamination parameters of mixed pressing are more stringent than those of ordinary pressing.

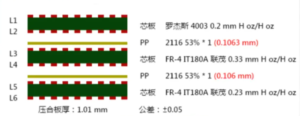

The following figure is the pressing structure diagram of the product:

In addition, the product’s via process uses copper paste plugging. Copper paste has excellent electrical conductivity. In high-frequency and high-speed circuits, signal transmission has very strict requirements on conductivity. Copper paste plugging can effectively reduce the resistance and loss of signal transmission and ensure the integrity and accuracy of signal transmission.

PCB also has metal edging and controlled depth groove design. Metal edging can enhance the mechanical strength of the product, prevent edge wear, and have a certain electromagnetic shielding effect to prevent circuit signal interference. Controlled depth groove can facilitate the installation and fixation of components. Reasonable controlled depth groove design can reduce signal interference. By placing some sensitive components or signal lines in specific controlled depth grooves, electromagnetic interference with other components or signal lines can be avoided, improving the quality and stability of signal transmission.