What is the difference between high-frequency circuit boards and ordinary circuit boards? Comprehensive analysis of advantages and disadvantages!

High-frequency circuit boards have higher operating frequencies and lower signal distortion rates, but their manufacturing costs are higher and manufacturing is more difficult. Ordinary circuit boards are relatively low-cost and simple to manufacture, but they cannot meet the working requirements of high-frequency circuits. This article comprehensively explains the differences and characteristics of these two circuit boards through comparisons in technical principles, material differences, design standards, manufacturing difficulty and other aspects.

1. Technical principles

The main difference between high-frequency circuit boards and ordinary circuit boards lies in the processing of electrical signals. In high-frequency circuits, the frequency of electronic signals exceeds 1MHz. At this time, the signal has extremely high frequency and transient response speed. Ordinary circuits can process low-frequency signals and process electrical signals in the range below 1MHz. Because the signal processing requirements of high-frequency circuits are more stringent, circuit boards equipped with high-frequency circuits are endowed with special capabilities such as high interconnection and low noise. Therefore, in order to ensure the normal operation of high-frequency circuit boards, high-frequency circuit boards need to have higher design and manufacturing standards.

2. Material differences

High-frequency circuit boards must be made of high-quality materials to meet their high-speed transmission-related properties. High-frequency circuit boards usually use silicone resin or PTFE (polytetrafluoroethylene) as the substrate material. In contrast, ordinary circuit boards generally use fiberglass, epoxy boards or multi-layer boards as the substrate materials. Among high-frequency materials, silicone and PTFE have the characteristics of lower performance loss, good high-frequency dielectric properties and excellent mechanical strength, while glass fiber and epoxy do not have such superior properties.

3. Design standards

The design standards of high-frequency circuit boards are relatively high, and it is necessary to fully consider the influence of the size of the circuit board, the position of the components and the board structure. In the PCB design of high-frequency circuit boards, design factors such as circuit trace width, line spacing, interlayer secants, no long ground and distributed capacitance need to be considered. Therefore, please note that great care must be taken during the design development of high-frequency circuit boards to ensure the reliability and quality of their functionality.

4. Manufacturing difficulty

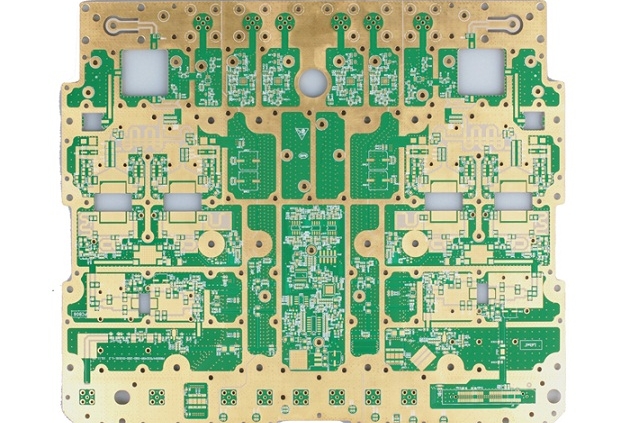

The manufacturing of high-frequency circuit boards requires the use of more complex processing, production and testing equipment, with higher manufacturing standards and technical requirements. Factors such as narrow circuit traces and apertures, higher precision, and concise circuits make high-frequency circuit boards more difficult to manufacture and the manufacturing cost is relatively high. But once these requirements are met, more accurate results and lower signal distortion rates can be achieved.

High-frequency circuit boards have higher operating frequencies and lower signal distortion rates, so they are suitable for products in the fields of high-speed communications, wireless communications, and high-frequency applications. At the same time, the manufacturing cost of high-frequency circuit boards is relatively high, and the design is also difficult. Ordinary circuit boards are relatively low-cost and simple to manufacture, but they cannot meet the working requirements of high-frequency circuits, so they can only be used in applications with lower operating frequencies.