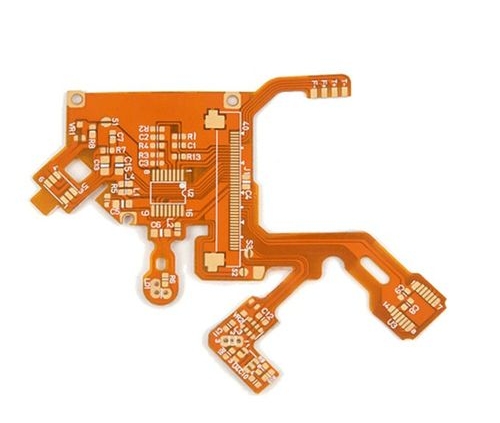

FPC flexible circuit board bending skills help you create tough electronic products!

In the manufacturing process of electronic products, FPC flexible circuit boards play a vital role. Its softness and foldability make the design of electronic products more flexible while also improving the durability of the product. However, bending FPC circuit boards is not a simple task and requires some skills and precautions.

1. Durability of fpc flexible circuit board

FPC flexible circuit boards have outstanding durability, which is mainly reflected in the following aspects.

Excellent flexibility: FPC flexible circuit boards use flexible base materials, so they can work under deformation conditions such as bending, twisting and folding. Compared with rigid circuit boards, fpc flexible circuit boards can adapt to more installation environments, thus improving the durability of the product.

High shock resistance: Due to the flexibility of the FPC flexible circuit board, when subjected to mechanical shock or vibration, compared with the rigid circuit board, the FPC circuit board can better resist and buffer the impact force, thereby reducing the risk of the circuit board risk of damage.

Reliable connectivity: FPC flexible circuit board uses pressure-sensitive adhesive connection method, which has good conductivity and reliability. Even under long-term use and frequent bending, the connection life on the circuit board is guaranteed, thereby increasing the service life of electronic products.

2. Bending skills help create tough electronic products

When using FPC flexible circuit boards for bending processing, the following are some practical tips to help create tough and durable electronic products.

Reasonable design of the bending area: When designing the bending area of the FPC flexible circuit board, the curvature and bending radius of the circuit board need to be fully considered. Reasonable bending area design can reduce stress concentration and reduce the risk of circuit board damage.

Choose the appropriate bending process: For the bending process of FPC flexible circuit boards, there are many methods to choose from, such as manual bending, mechanical bending, etc. According to different product requirements and circuit board characteristics, choosing the appropriate bending process can minimize circuit board damage.

Control the bending force and speed: During the bending process of FPC flexible circuit boards, you need to pay attention to controlling the bending force and speed to avoid excessive force and fast speed causing circuit board rupture. Appropriate force and speed can ensure the integrity and stability of the circuit board.

FPC flexible circuit boards show excellent durability in electronic products, can adapt to various installation environments and resist impact, and extend the service life of the product. At the same time, reasonable bending design and control of the bending process and speed help create tough and durable electronic products. It is believed that FPC flexible circuit boards will play an increasingly important role in the future design and manufacturing of electronic products.