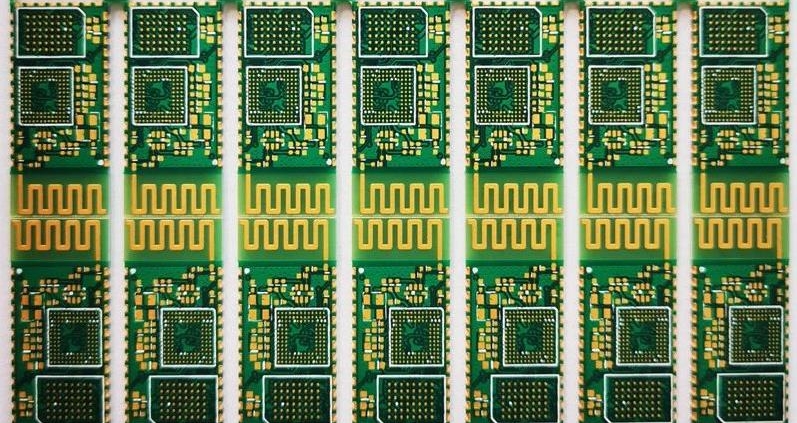

Detailed explanation of PCB immersion gold process: Make your electronic products more stable and reliable!

In the field of electronic manufacturing, PCB (Printed Circuit Board) serves as a bridge connecting electronic components, and its quality and stability are directly related to the performance and reliability of the entire electronic product. The immersion gold process, as a well-recognized PCB surface treatment process, provides higher stability and reliability for electronic products. Below, we will analyze the PCB immersion gold process in detail to give you a deeper understanding of its advantages and applications.

1. Overview of immersion gold technology

The immersion gold process, known as Electroless Nickel/Immersion Gold, is to plate a layer of nickel-phosphorus alloy on the surface of copper through a chemical reaction, and then plate a layer of gold on the surface of the nickel through a displacement reaction. This process not only makes the pad surface extremely flat, but also forms a protective film on the surface and sides, providing more possibilities for connecting electronic components.

2. Characteristics of immersion gold technology

Excellent weldability: The metal layer formed by the immersion gold process has good coplanarity and weldability, making the welding process smoother and reducing the risk of poor welding.

Excellent corrosion resistance: The immersed gold layer can effectively block the erosion of external oxygen, humidity and chemical substances, thereby extending the service life of the pad and improving the stability and reliability of the component.

High flatness: The immersion gold process can evenly deposit a layer of nickel and gold on the surface of the pad, making the surface smooth and flat, providing good conditions for welding.

Good electrical conductivity: Both the nickel-phosphorus alloy layer and the gold layer have excellent electrical conductivity, ensuring stable transmission of electronic signals.

3. Application of immersion gold technology

Immersion gold process PCB is widely used in electronic products such as mobile phones and computers. In these fields, the connection quality and stability of electronic components are critical to product performance and user experience. The application of immersion gold technology enables electronic products to maintain good stability and reliability in extreme environments, such as high temperature, high humidity or corrosive gas environments.

4. Control points of immersion gold process

Although the immersion gold process has many advantages, there are still some control points that need to be paid attention to during the actual production process to ensure its quality and stability. For example, the composition and concentration of the plating solution must be strictly controlled to ensure the uniformity and stability of the chemical reaction; at the same time, attention must be paid to controlling the thickness and uniformity of the coating to avoid problems such as uneven thickness or peeling of the coating.

The PCB immersion gold process provides higher stability and reliability for electronic products. By in-depth understanding of its principles, characteristics and applications, we can better utilize this process to provide strong support for the manufacturing and research and development of electronic products. In the future, with the continuous development and innovation of electronic technology, we believe that the immersion gold process will provide a stronger guarantee for the stability and reliability of electronic products.