Customized thick copper circuit board, the best choice for stability and reliability!

Circuit boards play a vital role in electronic equipment, and the customization of their thick copper plates is crucial to the stability and reliability of the equipment. This article will discuss in detail the customization of thick copper plates for circuit boards from four aspects: the advantages, customization process, application scenarios and future development trends of thick copper plates.

1. Advantages

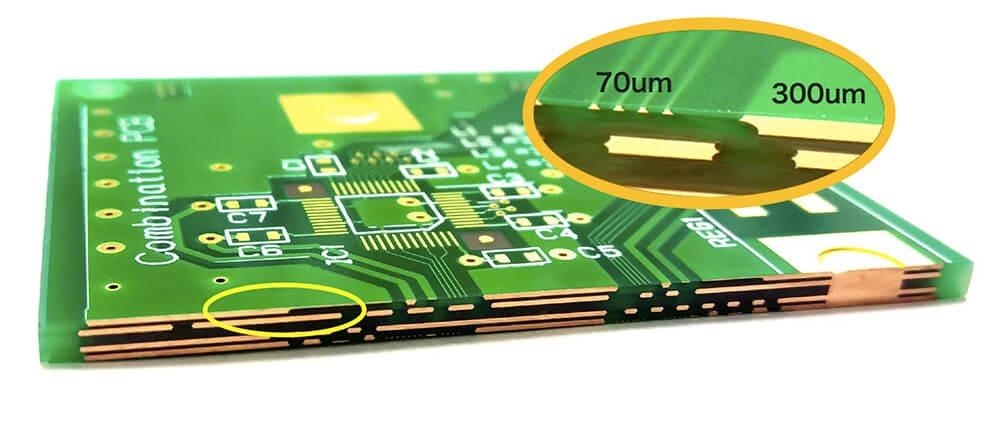

As a special form of circuit board, thick copper plate has excellent thermal conductivity, good electrical performance and high strength, which plays a significant role in improving the stability and reliability of circuit boards. The thick copper plate can not only reduce the temperature rise of the circuit board and improve the heat dissipation performance, but also reduce the line loss of the circuit board and improve the accuracy of signal transmission. In special application areas such as high frequency and high power, thick copper plates are an indispensable choice. The advantage of thick copper plates is that they can provide better current carrying capacity, reduce the parasitic resistance of the circuit board, reduce the temperature of the circuit board, and extend the service life of the equipment. Therefore, customizing thick copper circuit boards can improve the reliability and stability of electronic equipment and is favored by more and more customers.

2. Customization process

The customization of thick copper plates for circuit boards usually requires the following processes: design confirmation, process discussion, material selection, production and processing, quality inspection and other links. The design confirmation stage is to determine customer needs and specifications. The process discussion stage includes determining the production process and requirements. The material selection stage is to select suitable copper and aluminum-based materials. The production and processing stage is to make circuit boards according to the design requirements. The quality inspection stage is to inspect the finished product. Conduct strict testing to ensure reliable quality. Due to the high production requirements for thick copper sheets for circuit boards, customers need to work closely with suppliers to ensure that every step of the process meets the requirements, so as to obtain customized products with reliable quality.

3. Application scenarios

Circuit board thick copper plates are widely used in communication equipment, military equipment, medical equipment, aerospace and other fields. In communication equipment, thick copper plates can increase signal transmission rate, reduce signal distortion rate, and ensure stable operation of equipment; in military equipment, thick copper plates have strong anti-interference and earthquake resistance, and can adapt to various harsh environments; in medical equipment Medium and thick copper plates can improve the safety and stability of equipment and ensure the accuracy of medical operations; in the aerospace field, thick copper plates can meet the requirements for lightweight and high performance of equipment and ensure long-term stable operation of equipment.

4. Future development trends

As the requirements for stability and reliability of electronic equipment continue to increase, the market demand for thick copper sheets for circuit boards will continue to grow. In the future, customized thick copper plates will pay more attention to the selection of environmentally friendly materials and develop more energy-saving and environmentally friendly thick copper plates for circuit boards; at the same time, with the development of technologies such as intelligence and the Internet of Things, thick copper plates for circuit boards will play an important role in the development of new smart devices. It has an important impact on applications and becomes an indispensable key component in future electronic devices.

The customization of thick copper plates for circuit boards is the best choice to improve the stability and reliability of electronic equipment, which is of great significance and broad prospects. By continuously optimizing the process flow and expanding the application fields, circuit board thick copper plates will be more widely used in various types of electronic equipment in the future, injecting more vitality into the development of the electronics industry.