Automotive PCB board process requirements, how to ensure driving safety and stability?

Automotive PCB board technology is an indispensable key link in modern automobile manufacturing. It is directly related to the driving safety and stability of the car. This article will elaborate on the automotive PCB board process requirements from four aspects and discuss how to ensure driving safety and stability.

1. Design requirements

Design is the basis of automotive PCB board technology and is related to the stability and reliability of the entire electronic system. The wiring of automobile PCB boards should be reasonable to avoid interference and electromagnetic compatibility issues to ensure the stability of circuit transmission. The impact of environmental factors such as temperature and humidity on the PCB board should also be considered in the design, and appropriate protection measures should be selected, such as moisture-proof, dust-proof, etc., to improve the durability of the PCB board. In addition, the repairability of the PCB board needs to be considered to facilitate later maintenance and upgrades to ensure driving safety.

2. Material selection

The correct selection of PCB board materials is crucial to ensuring driving safety and stability. Materials with good high-temperature properties should be selected to adapt to the high-temperature requirements of the automotive working environment. The materials should also have lower dielectric loss and better signal transmission performance to improve signal stability. For automotive PCB boards that require fire resistance, materials with better flame retardant properties should be selected to ensure that the fire source can be extinguished in time in the event of an accident. Taking these factors into consideration, selecting appropriate materials can improve the performance and reliability of automotive PCB boards.

3. Manufacturing process

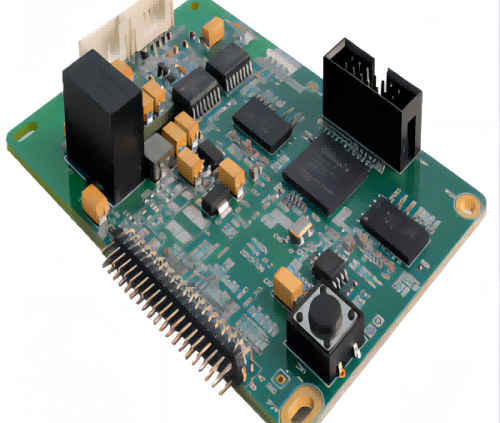

The manufacturing process is a key link in ensuring the quality of automotive PCB boards. A good printed circuit board (PCB) manufacturing process can ensure the accuracy and stability of the circuit and improve the overall quality of the board. A reasonable surface treatment process can improve the connection stability between the PCB board and components, reduce contact resistance, and improve the circuit quality. transmission efficiency. The assembly process of PCB is also very important to ensure welding quality and reliability and prevent circuit failures caused by poor welding. Through good manufacturing technology, the quality and stability of automobile PCB boards can be ensured and driving safety can be improved.

4. Quality control

Automotive PCB board process requirements also require strict quality control measures. Develop and implement strict standards and specifications to ensure that the production of PCB boards meets the specified requirements. Necessary quality inspections and tests are performed during the production process to ensure that every link meets the requirements to reduce the production of defective products. Establish a complete quality traceability system to track and analyze possible quality problems and take corrective measures in a timely manner. Through quality control, PCB board quality problems can be avoided to the greatest extent and the safety and stability of driving can be improved.

Automotive PCB board process requirements play a vital role in ensuring driving safety and stability. Only when all aspects meet the standard requirements can the quality and stability of the automotive PCB board be guaranteed. The automobile manufacturing industry should attach great importance to these requirements in practice, strive to improve the driving safety and stability of automobiles, and provide users with a better driving experience.