Analysis of the causes of lack of copper in half holes of PCB boards and their effects!

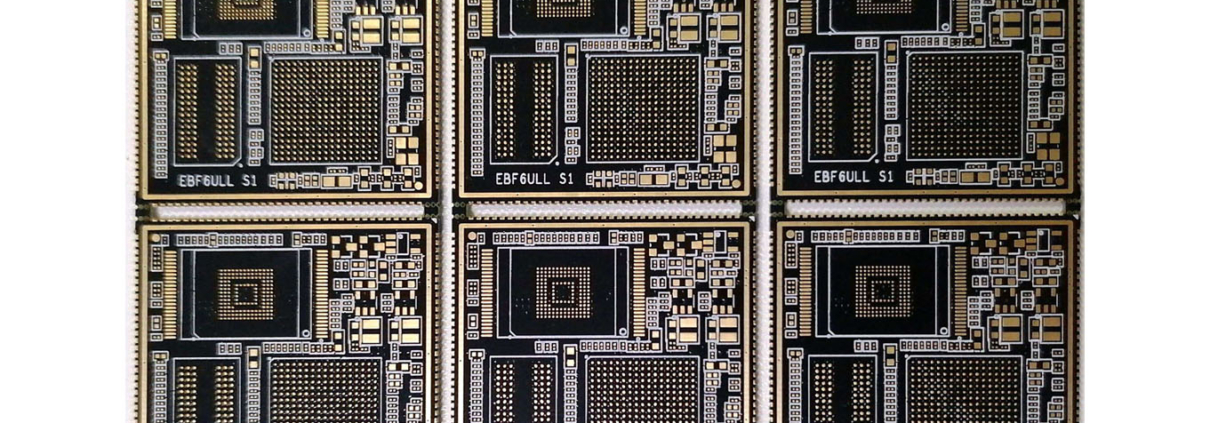

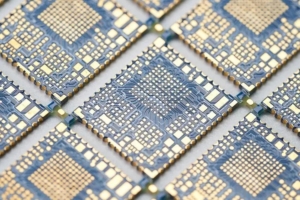

In the electronics manufacturing industry, PCB (Printed Circuit Board) board serves as a “neural network” connecting electronic components, and its quality directly affects the performance and stability of the entire electronic device. As a common manufacturing problem, half-hole copper deficiency in PCB boards has complex causes and far-reaching consequences. This article will deeply analyze the reasons for the lack of copper in the half-hole of the PCB board and discuss its possible impact.

1. Analysis of the causes of lack of copper in half holes of PCB boards

Drilling process issues

Insufficient precision of drilling equipment: Low-precision drilling equipment may result in inconsistent hole sizes, rough or damaged hole walls.

Drill bit selection and wear: Unsuitable drill bits or excessively worn drill bits will affect the quality of drilling.

Improper drilling parameter settings: Unreasonable settings such as feed speed, rotation speed, etc. will also cause damage to the hole wall.

Electroplating copper process issues

Electroplating solution composition and concentration: The copper ion concentration in the electroplating solution is too low or too high, which may affect the electroplating effect.

Electroplating solution temperature and pH value: Improper temperature or pH value will affect the adhesion and uniformity of the electroplated copper layer.

Current density and time: The current density is too high or too small, and the plating time is too short or too long, which will lead to poor copper layer quality.

plate problem

Uneven material of the board: There are impurities or inconsistent fiber directions inside the board, which will affect the adhesion and uniformity of the electroplated copper layer.

Improper plate pretreatment: If the pretreatment process such as oil removal and rust removal is not in place, it will affect the subsequent electroplating effect.

Operational and Management Issues

Insufficient operator skills: The skill level of operators directly affects product quality.

Strict quality inspection: Strict quality inspection of semi-finished products and finished products may cause problematic products to flow into the next process.

2. The impact of lack of copper in the half hole of PCB board

Reduced electrical performance: Lack of copper in half holes can lead to poor circuit connections, increase resistance, and reduce the electrical performance of electronic devices.

Reduced equipment stability: Poor circuit connections may cause short circuits, open circuits and other faults during operation of the equipment, reducing the stability and reliability of the equipment.

Increased production costs: The lack of copper in half holes will increase the scrap rate and repair rate of products, leading to an increase in production costs. At the same time, more time and resources may need to be invested in technical improvements and quality control to solve this problem.

Damage to market competitiveness: PCB board quality issues are an important factor affecting a company’s brand image and reputation. If the product has quality problems such as half-hole copper shortage, it will affect customers’ trust in the company and reduce market competitiveness.

3. Solution Strategies and Suggestions

Improve equipment and process level: introduce advanced drilling equipment and electroplating equipment, optimize process parameter settings, and ensure the stability and reliability of the drilling and electroplating process.

Strictly screen and inspect boards: Strictly screen and inspect the base materials of PCB boards to ensure that the quality of the boards meets the requirements. At the same time, the pretreatment process control of the plate is strengthened to ensure that the hole wall is clean and free of impurities.

Strengthen operation and management training: improve the skill level of operators and strengthen the rigor of quality inspection. Establish a complete quality traceability system to promptly trace and analyze problematic products.

Adopt new technologies and new materials: Explore the use of new technologies and new materials to improve the manufacturing quality and performance of PCB boards. For example, advanced technologies such as laser drilling technology and nano-plating technology are used to improve product accuracy and reliability.

The lack of copper in the half hole of the PCB board is a problem that needs attention. By in-depth analysis of its causes and adopting effective solution strategies, we can reduce the incidence of half-hole copper shortage problems, improve the quality and performance of PCB boards, and thereby enhance the market competitiveness of enterprises.