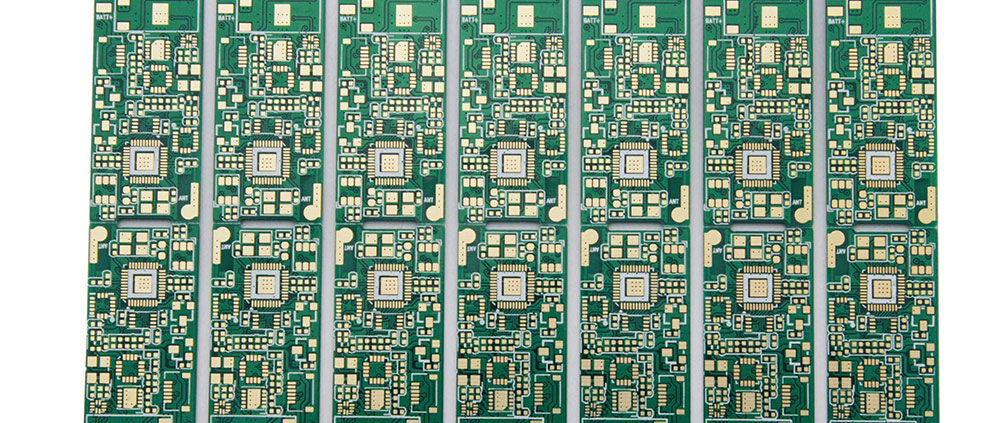

Accurate to the point, super cost-effective! Medical circuit board customization price revealed!

Medical circuit board customization is one of the key links in the field of medical equipment. It embodies the requirements of precision and the pursuit of ultra-high cost performance. With the continuous development of medical technology, electronic components are increasingly used in medical equipment, and the price and quality of customized circuit boards directly affect the performance and reliability of medical equipment. This article will delve into the price of medical circuit board customization and elaborate on it from four aspects: cost, design, quality and market demand.

1. Cost control

The price of medical circuit board customization is first subject to cost factors. The procurement of electronic components, PCB manufacturing, patch welding, testing and inspection will all incur certain costs. Among them, the procurement of electronic components is an important part. The prices of components of different specifications, brands and quality levels vary greatly. The cost of equipment, labor and materials required in the manufacturing and assembly process also have an impact on the final price. Therefore, when customizing medical circuit boards, effective cost control is the key to ensuring reasonable prices.

2. Design requirements

Medical circuit board customization requires precision because the stability and reliability of medical equipment are crucial to the safety of patients. Design engineers need to carefully design circuit boards based on different medical equipment needs to ensure the stability and performance of each functional module. The complexity and technical requirements of the design will directly affect the price of medical circuit boards. At the same time, factors such as circuit board layout, heat dissipation, and EMC also need to be considered during the design stage to ensure the normal operation of medical equipment.

3. Quality Assurance

As a core component of medical equipment, medical circuit boards have particularly important quality requirements. During the production process, a strict quality management system needs to be followed to ensure product reliability and stability. This includes quality selection of parts, quality control of production lines, and environmental electrostatic protection. Through strict quality inspection and reliability testing, we ensure the quality of medical circuit boards and achieve long-term stable operation. However, in order to meet high-quality requirements, more costs are required for medical circuit board customization.

4. Market demand

The price of medical circuit board customization is also affected by market demand. The medical equipment market is highly competitive, and different manufacturers have different needs for product customization. Large medical equipment requires more complex circuit board design and higher quality assurance, so customization prices will be relatively high. The requirements for circuit boards for small medical equipment may be relatively simple, and the customization price is relatively low. At the same time, the market demand for medical circuit boards with special functions and high performance will also affect the price of customization.

The price of medical circuit board customization is affected by multiple factors. When customizing medical circuit boards, manufacturers need to fully consider these factors and, while meeting performance and quality requirements, try to control costs to provide products with ultra-high cost performance. Only in this way can the customized price of medical circuit boards truly meet market demand and play its important role in medical equipment.