A must-read for engineers! What factors affect PCB stackup design?

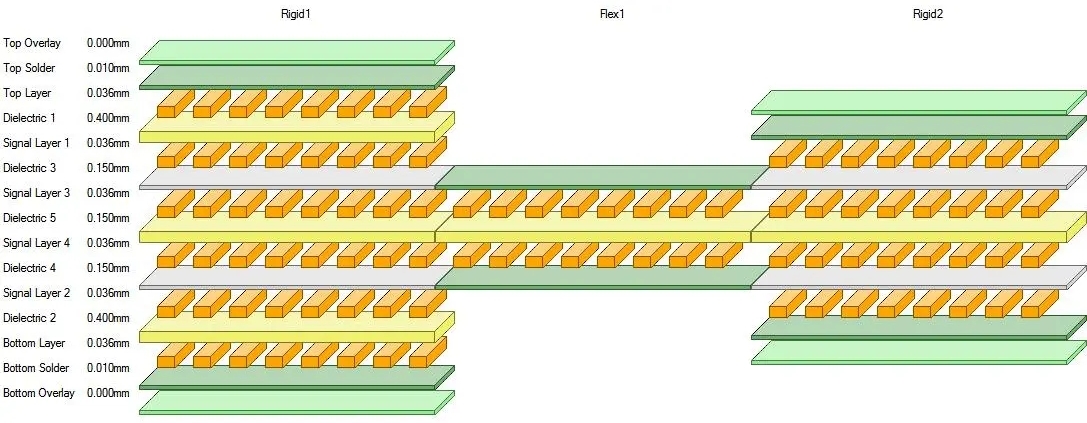

When designing a PCB (printed circuit board), one of the most basic issues to consider is how many wiring layers, ground planes and power planes are needed to achieve the functions required by the circuit. The wiring layers, ground planes and power planes of the printed circuit board The determination of the number of plane layers is related to requirements such as circuit function, signal integrity, EMI, EMC, and manufacturing costs. For most designs, there are many conflicting requirements in factors such as PCB performance requirements, target cost, manufacturing technology, and system complexity. The stack-up design of the PCB is usually determined by a compromise after considering various factors. High-speed digital circuits and whisker circuits usually adopt multi-layer board designs. What factors affect PCB stackup design?

1. Layering

In a multi-layer PCB, it usually contains a signal layer (S), a power (P) plane and a ground (GND) plane. Power planes and ground planes are usually solid planes without separation, and they will provide a good low-impedance current return path for current from adjacent signal traces. The signal layer is mostly located between these power or ground reference plane layers, forming a symmetrical stripline or an asymmetrical stripline. The top and bottom layers of multi-layer PCBs are usually used to place components and a small number of traces. These signal traces must not be too long to reduce direct radiation generated by the traces.

2. Determine the single power supply reference plane (power plane)

The use of decoupling capacitors is an important measure to solve power supply integrity. Decoupling capacitors can only be placed on the top and bottom layers of the PCB. The traces, pads, and vias of the decoupling capacitor will seriously affect the effect of the decoupling capacitor. This requires that the traces connected to the decoupling capacitors should be as short and wide as possible during design, and the wires connected to the vias should also be considered. Keep it as short as possible. For example, in a high-speed digital circuit, you can place decoupling capacitors on the top layer of the PCB, assign layer 2 to the high-speed digital circuit (such as a processor) as the power layer, layer 3 as the signal layer, and layer 4 Set to high-speed digital circuit ground.

In addition, try to ensure that the signal traces driven by the same high-speed digital device use the same power layer as the reference plane, and this power layer is the power supply layer of the high-speed digital device.

3. Determine the multi-power reference plane

The multi-supply reference plane will be divided into several physical areas with different voltages. If there is a signal layer next to the multi-power layer, the signal current on the nearby signal layer will encounter an unideal return path, causing gaps in the return path. For high-speed digital signals, this unreasonable return path design may cause serious problems, so it is required that high-speed digital signal wiring should be kept away from multi-power reference planes.

4. Determine multiple ground reference planes (ground planes)

Multiple ground reference planes (ground layers) can provide a good low-impedance current return path, which can reduce common-mode EMl. Ground planes and power planes should be tightly coupled, and signal layers should be tightly coupled to adjacent reference planes. This can be achieved by reducing the thickness of the media between layers.

5. Reasonable design of wiring combinations

The two layers spanned by a signal path are called a “routing combination.” The best routing combination design avoids return current flow from one reference plane to another, but flows from one point (plane) of a reference plane to another point (plane). In order to complete complex wiring, interlayer conversion of wiring is inevitable. When converting between signal layers, it is necessary to ensure that the return current can flow smoothly from one reference plane to another. In a design, it makes sense to treat adjacent layers as a routing group. If a signal path needs to span multiple layers, it is usually not a reasonable design to use it as a routing group, because a path through multiple layers is not clear for return current. Although the ground bounce can be reduced by placing decoupling capacitors near the vias or reducing the dielectric thickness between the reference planes, it is not a good design.

6. Set the wiring direction

On the same signal layer, the direction of most wiring should be consistent and orthogonal to the wiring direction of adjacent signal layers. For example, you can set the wiring direction of one signal layer to the “Y-axis” direction, and set the wiring direction of another adjacent signal layer to the “X-axis” direction.

7. Adopt an even-numbered layer structure

From the designed PCB stackup, it can be found that the classic stackup design is almost all even-numbered layers, not odd-numbered layers. This emergency is caused by a variety of factors, as shown below.

It can be understood from the manufacturing process of printed circuit boards that all conductive layers in the circuit board are saved on the core layer. The material of the core layer is usually a double-sided cladding board. When the core layer is fully utilized, the conductive layer of the printed circuit board The number is even.

Even-layer printed circuit boards have cost advantages. Due to the lack of one layer of dielectric and copper coating, the cost of raw materials for odd-numbered printed circuit boards is slightly lower than the cost of even-numbered printed circuit boards. However, because odd-numbered layer printed circuit boards require a non-standard laminated core layer bonding process based on the core layer structure process, the processing cost of odd-numbered layer printed circuit boards is significantly higher than even-numbered layer printed circuit boards. Compared with the ordinary core structure, adding copper cladding outside the core structure will lead to a decrease in production efficiency and a prolongation of the production cycle. The outer core layer also requires additional processing before lamination and bonding, which increases the risk of scratches and incorrect etching of the outer layer. The added outer layer treatment will significantly increase manufacturing costs.

When the inner and outer layers of a printed circuit board are cooled after the multi-layer circuit bonding process, different lamination tensions will cause the printed circuit board to bend to varying degrees. And as the thickness of the board increases, the risk of bending of a composite printed circuit board with two different structures increases. Odd-numbered circuit boards are prone to bending, while even-numbered layers of printed circuit boards can prevent the circuit board from bending.

During design, if there are an odd number of layers, you can use the following method to increase the number of layers.

If you design a printed circuit board with an even number of power layers and an odd number of signal layers, you can use the method of adding signal layers. The added signal layer will not lead to an increase in cost, but can shorten the processing time and improve the quality of the printed circuit board.

If you design a printed circuit board with an odd number of power layers and an even number of signal layers, you can use the method of adding power layers. Another simple method is to add a ground layer in the middle of the stack without changing other settings, that is, first lay out the odd-numbered printed circuit board layers, and then copy a ground layer in the middle.

In microwave circuits and mixed media (media with different dielectric constants) circuits, a blank signal layer can be added near the center of the PCB stackup to minimize stackup imbalance.

8. Cost considerations

In terms of manufacturing cost, with the same PCB area, the cost of multi-layer circuit boards is definitely higher than single-layer and double-layer circuit boards, and the more layers, the higher the cost. However, when considering factors such as circuit function and circuit board miniaturization, and ensuring signal integrity, EMl, EMC and other performance indicators, multi-layer circuit boards should be used as much as possible. Comprehensive evaluation shows that the cost difference between multi-layer circuit boards and single- and double-layer circuit boards is not much higher than expected.