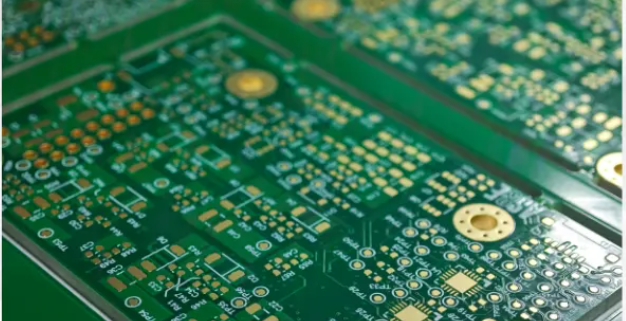

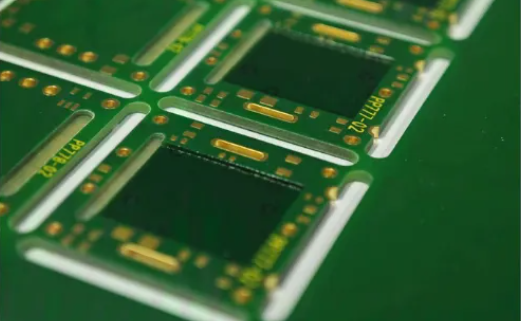

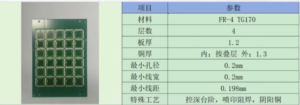

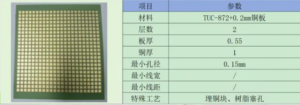

14-layer thick copper PCB

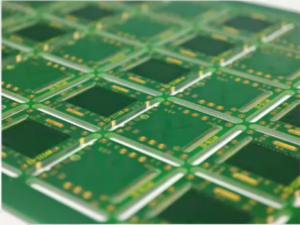

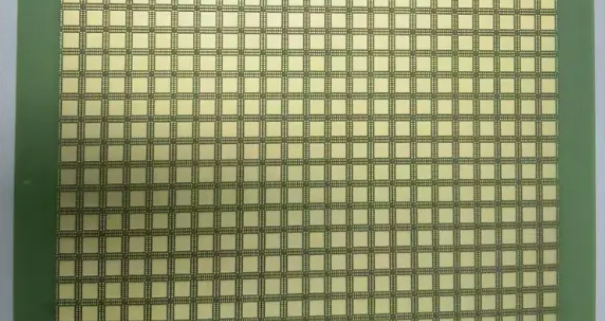

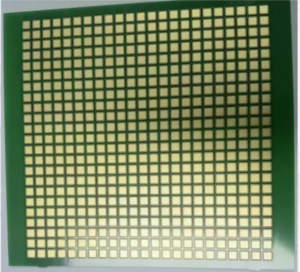

In the field of electronic circuits, the quality and performance of PCB directly affect the overall performance of electronic devices. We bring you a 14-layer thick copper board. Let us take a deeper look at the 14-layer PCB with both inner and outer layers of 2oz and appreciate its unique charm and advantages.

The 2oz copper foil thickness of the inner and outer layers gives this PCB excellent current carrying capacity. In high-power electronic devices, such as power supplies, motor drive devices, etc., it can easily cope with the transmission needs of large currents, effectively reduce line impedance, and reduce power loss, thereby improving the energy efficiency and stability of the equipment. Whether it is the core control board of industrial automation equipment or the power distribution board of high-end servers, 2oz copper thick PCB can provide reliable power support.

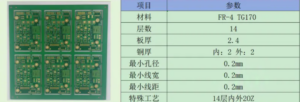

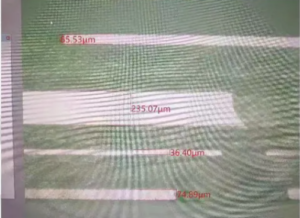

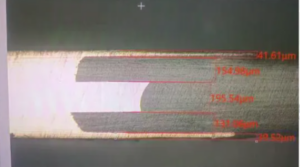

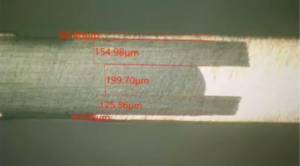

Let’s take a look at its slice diagram:

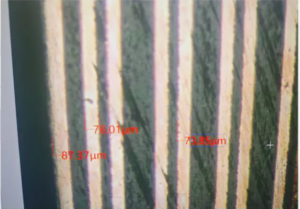

The 14-layer multi-layer structure design provides a good shielding and isolation environment for signal transmission. The reasonable layout and wiring between each layer, combined with the stability of 2oz copper foil, can effectively control signal transmission, crosstalk and other issues. For application scenarios with extremely high requirements for signal quality, such as high-speed digital circuits and radio frequency communication circuits, this PCB can ensure the integrity and accuracy of the signal, allowing high-speed and stable data transmission, laying a solid foundation for the high-performance operation of the equipment. For example, in the signal processing module of a 5G base station, it can ensure the fast and accurate interaction of massive data!