Why is it important to understand the pros and cons of high frequency microwave circuit boards?

High-frequency microwave circuit board is a circuit board specially used for high-frequency microwave signal transmission, which has unique advantages and limitations. By understanding its advantages and disadvantages, we can better apply and optimize this circuit board and improve product quality and performance.

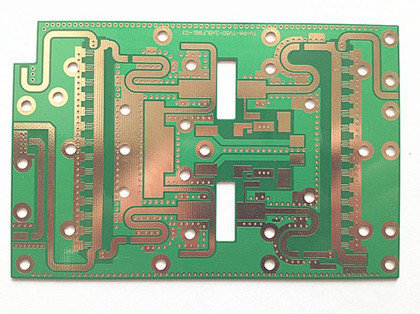

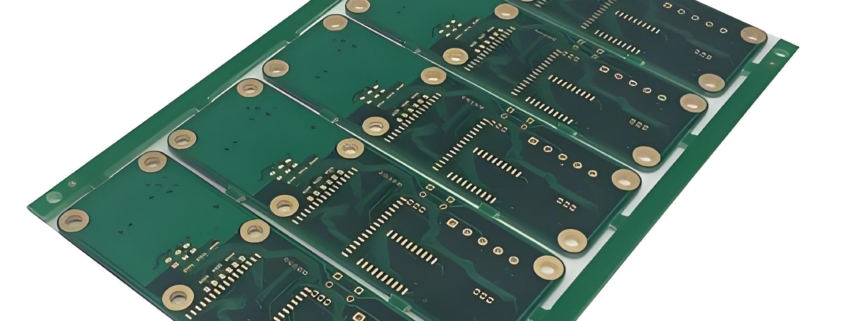

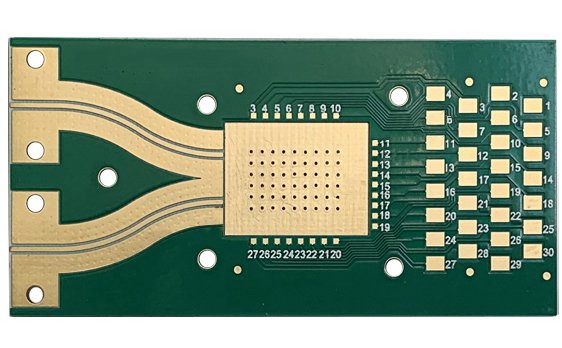

First, let us understand the advantages of high frequency microwave circuit boards. High-frequency microwave PCB circuit board has excellent high-frequency characteristics and can show lower signal loss and higher signal transmission efficiency in high-frequency microwave signal transmission. In addition, it also has good anti-interference performance and can effectively resist the impact of external interference on signal transmission. In addition, the manufacturing process of high-frequency microwave PCB circuit boards is relatively mature and can meet the needs of mass production.

However, high-frequency microwave circuit boards also have some limitations. First, its manufacturing process is relatively complex and requires highly precise processing and production equipment, so it is prone to process challenges during the production process. High-frequency microwave circuit boards have higher material requirements and require the use of specific high-frequency materials, which also increases the cost and manufacturing difficulty. In addition, high-frequency microwave PCB circuit boards need to consider more high-frequency characteristics in the design and layout, and the technical requirements for designers are also higher.

Understanding the advantages and disadvantages of high-frequency microwave PCB circuit boards is crucial for the electronics industry and communications field. Only by fully understanding its advantages and disadvantages can we better apply and optimize this circuit board and improve product quality and performance. Through targeted optimization and improvement, we can better meet the needs of high-frequency microwave signal transmission and provide more reliable technical support for development and innovation in the communications field.