Which wiring pattern is better to use when designing PCB?

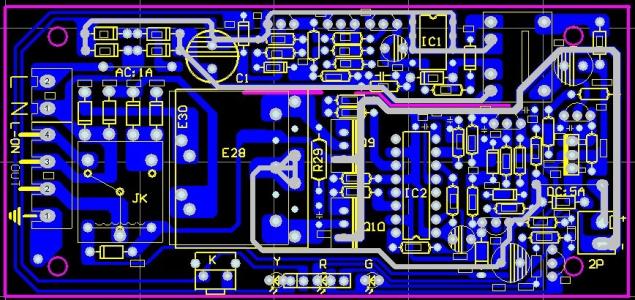

In PCB design, the use of appropriate trace patterns has an important impact on the performance and reliability of the circuit. The following are several common wiring forms. Each has its own advantages. Choosing the appropriate form according to specific design requirements will be more conducive to improving the performance and reliability of the circuit.

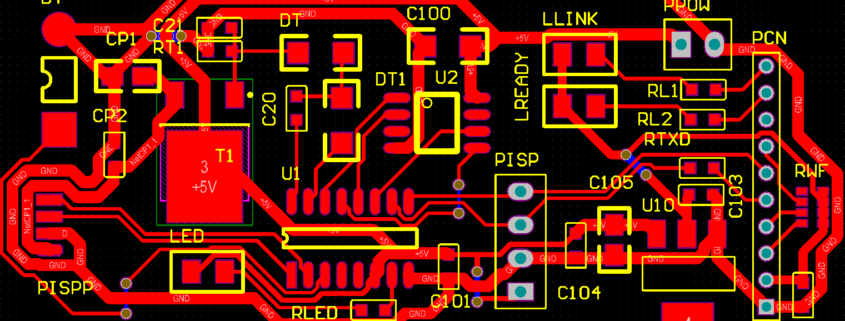

1. Straight-line routing: Straight-line routing is the simplest and most common form of routing. It has the advantage of being direct and fast, which can reduce the delay of signal transmission. In circuit design, there are often some signal lines that must be connected in a straight line, so using straight lines can better meet this requirement.

2. Bend the wiring at a 45-degree angle: When the signal line needs to be introduced into or out of the board, bending the wiring at a 45-degree angle can reduce the reflection and interference of the signal line. Compared to right-angle bends, 45-degree bends can better maintain signal integrity.

3. Arc routing: Arc routing can reduce radiation and crosstalk of signal lines, especially for high-frequency signals. If there are high-frequency signal lines in the design, arc routing can reduce signal loss and distortion.

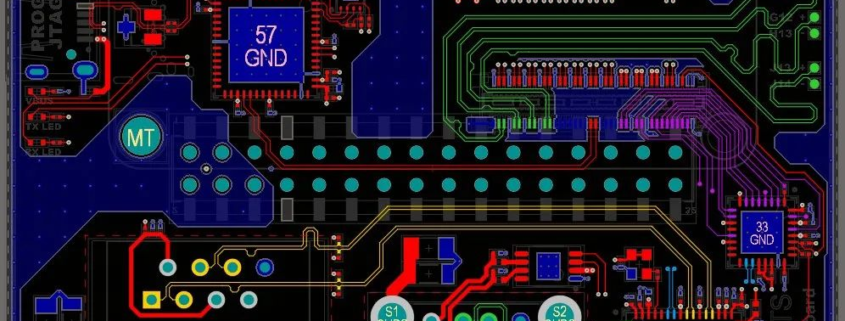

4. Node cross wiring: In design, we often encounter situations where cross signals need to be connected. When conducting node cross wiring, pay attention to the distance between signal lines to prevent signal crosstalk. Interlayer wiring, ground cutting and other methods can be used to reduce signal interference.

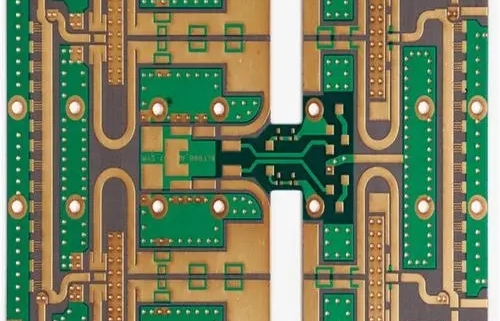

5. Hard-flex wiring: Hard-flex wiring refers to signal transmission through inter-layer connections. It improves design flexibility and reliability. Rigid flexible wiring is widely used in complex high-density circuit design, multi-layer board design, etc.

6. Top/bottom traces: In multilayer board designs, top and bottom traces can be used for shorter signal transmission paths, thereby reducing interlayer vias and delays. At the same time, top/bottom wiring can provide better shielding effect and reduce signal interference.

Although several common wiring forms are listed above, in actual design, multiple factors need to be considered to select the appropriate form. For example, the frequency characteristics of the circuit, noise tolerance, power consumption requirements, and process constraints, etc. When routing, you also need to pay attention to the separation between signals, power supplies, and ground wires, and rationally use ground wire shielding technology.

In short, choosing the appropriate trace pattern is crucial to the performance and reliability of the circuit. Based on the specific design requirements and circuit characteristics, designers should comprehensively consider various factors and select the best wiring form to optimize the circuit design.