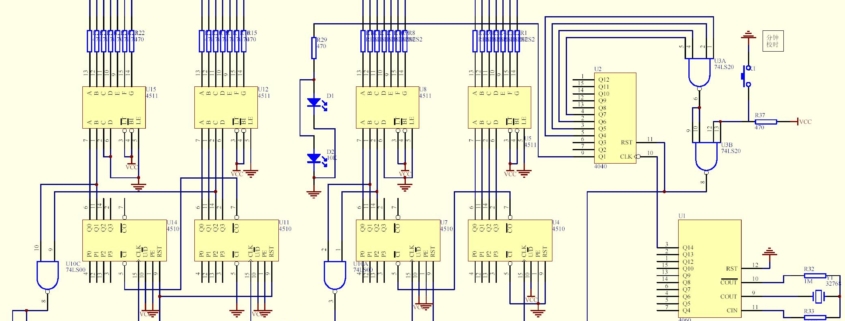

How to place RF circuit and digital circuit on PCB board at the same time?

If analog circuits (radio frequency) and digital circuits (microcontrollers) work alone, they may work well, but once they are put on the same circuit board and work together using the same power supply, the entire system is likely to be unstable. . This is mainly because the digital signal frequently swings between ground and positive power (3 V), and the period is extremely short, often on the ns level. Due to the large amplitude and small switching time, these digital signals contain a large number of high-frequency components that are independent of the switching frequency. In the analog part, the signal transmitted from the antenna tuning loop to the receiving part of the wireless device is generally less than 1μV.

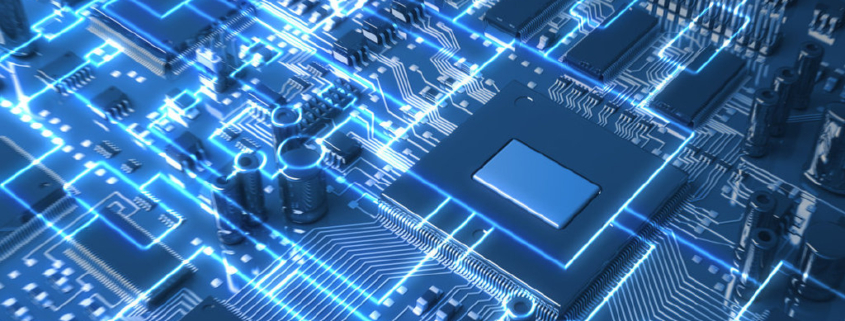

Failure to adequately isolate sensitive lines and noisy signal lines is a common problem. As mentioned above, digital signals have high swings and contain large amounts of high-frequency harmonics. If digital signal traces on a PCB are placed adjacent to sensitive analog signals, high-frequency harmonics may couple through. The sensitive nodes of RF devices are usually the loop filter circuit of the phase-locked loop (PLL), the external voltage-controlled oscillator (VCO) inductor, the crystal reference signal and the antenna terminal. These parts of the circuit should be handled with special care.

Because the input/output signals have a swing of several V, digital circuits are generally acceptable for power supply noise (less than 50 mV). Analog circuits are quite sensitive to power supply noise, especially glitch voltages and other high-frequency harmonics. Therefore, routing power lines on PCBs containing RF (or other analog) circuits must be more careful than routing on ordinary digital circuit boards, and automatic routing should be avoided. It should also be noted that a microcontroller (or other digital circuit) will suddenly draw most of the current for a short period of time during each internal clock cycle. This is because modern microcontrollers are designed using a CMOS process.

RF circuit boards should always have a ground layer connected to the negative pole of the power supply. If not handled properly, some strange phenomena may occur. This may be difficult for a digital circuit designer to understand because most digital circuit functions perform well even without a ground plane. In the RF band, even a short wire can act like an inductor. A rough calculation shows that the inductance per mm length is about 1 nH, and the inductive reactance of a 10 mm PCB line at 434 MHz is about 27 Ω. If the ground layer is not used, most ground wires will be long and the circuit will not be able to guarantee the design characteristics.

This is often overlooked in circuits that contain RF and other parts. In addition to the RF section, there are usually other analog circuits on the board. For example, many microcontrollers have built-in analog-to-digital converters (ADCs) for measuring analog inputs as well as battery voltage or other parameters. If the RF transmitter’s antenna is located near (or on) this PCB, the emitted high-frequency signal may reach the analog input of the ADC. Don’t forget that any circuit trace may act like an antenna, emitting or receiving RF signals. If the ADC input is not processed properly, the RF signal may self-excite in the ESD diode of the ADC input, causing ADC deviation.

All connections to the ground plane must be kept as short as possible, and ground vias should be placed at (or very close to) the component pads. Never allow two ground signals to share a ground via, as this may cause crosstalk between the two pads due to the via connection impedance. Decoupling capacitors should be placed as close to the pins as possible, and capacitive decoupling should be used at each pin that needs decoupling. Using high quality ceramic capacitors with dielectric type “NPO”, the “X7R” will work well in most applications. Ideally the capacitor value should be chosen so that its series resonance is equal to the signal frequency.

For example, at 434 MHz, an SMD-mounted 100 pF capacitor will work well. At this frequency, the capacitive reactance of the capacitor is about 4 Ω, and the inductive reactance of the via is also in the same range. The series connected capacitors and vias form a notch filter for the signal frequency, enabling effective decoupling. At 868 MHz, a 33 pF capacitor is an ideal choice. In addition to the small value capacitor for RF decoupling, a large value capacitor should also be placed on the power line to decouple low frequencies. You can choose a 2. 2 μF ceramic or 10 μF tantalum capacitor.

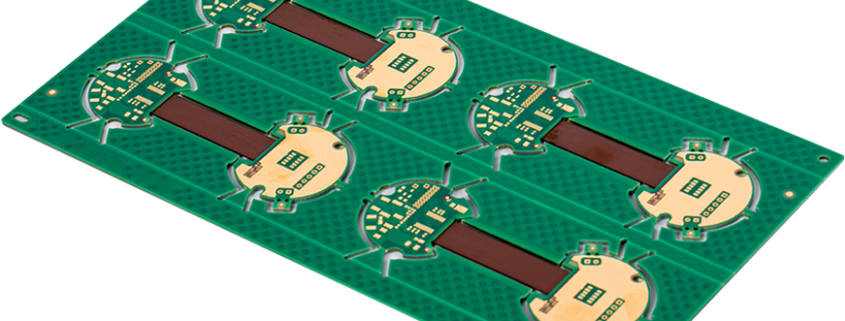

Star wiring is a well-known technique in analog circuit design. Star wiring – Each module on the circuit board has its own power line from a common power supply point. In this case, star wiring means that the digital and RF parts of the circuit should have their own power lines, which should be separately decoupled close to the IC. This is a separation from numbers

An effective method for summing up power supply noise from the RF section. If a module with severe noise is placed on the same circuit board, an inductor (magnetic bead) or a small value resistor (10 Ω) can be connected in series between the power line and the module, and a tantalum capacitor of at least 10 μF must be used for these. Decoupling of the module’s power supply. Such modules are RS 232 drivers or switching power supply regulators.

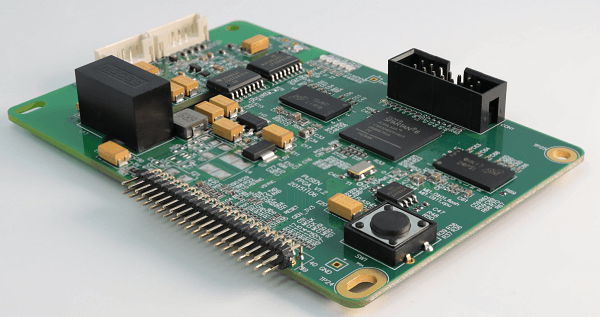

In order to reduce interference from the noise module and surrounding analog parts, the layout of each circuit module on the board is important. Sensitive modules (RF section and antenna) should always be kept away from noisy modules (microcontroller and RS 232 driver) to avoid interference. As mentioned above, RF signals can cause interference to other sensitive analog circuit modules such as ADCs when transmitted. Most problems occur at lower operating frequency bands (such as 27 MHz) and at high power output levels. It is a good design practice to decouple sensitive points with RF decoupling capacitors (100pF) connected to ground.

If you use cables to connect the RF circuit board to external digital circuits, use twisted pair cables. Each signal line must be twisted together with the GND line (DIN/GND, DOUT/GND, CS/GND, PWR_UP/GND). Remember to connect the RF circuit board and the digital application circuit board with the GND line of the twisted pair cable, and the cable length should be as short as possible. The lines supplying power to the RF circuit board must also be twisted with GND (VDD/GND).