18-layer mechanical blind hole + step + back drilling + immersion gold + gold plating 30U + M6 high-speed circuit board

With the development of science and technology, information and communication technology are changing with each passing day, and people’s requirements for computer performance are getting higher and higher. Correspondingly, the hardware requirements for computer communication equipment are also getting higher and higher. PCB is the basic product of electronic equipment, and its high-end precision determines the performance of the entire finished computer communication equipment!

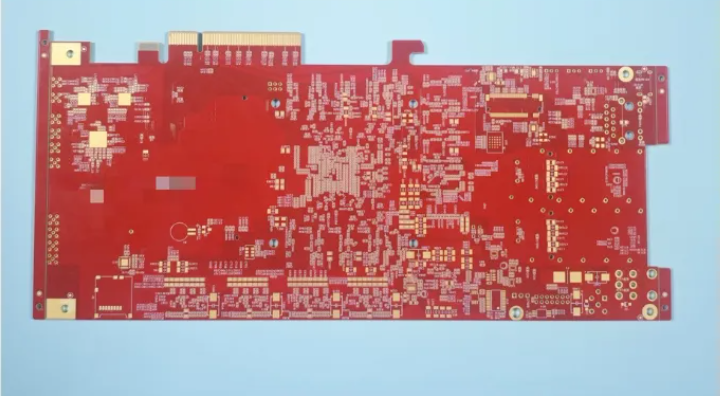

Today, SHENZHEN BEST PCBA CO., LIMITED brings you an FPGA acceleration card for high-performance computing and network acceleration devices. Let’s first take a look at what the PCB board looks like.

The bright red solder mask ink, immersion gold + electroplated gold finger 30U” surface treatment process make the whole product look very high-end. But what really attracts people to this product is not just its appearance, but its complex design and precise production process.

First of all, let’s take a look at its step process.

The conventional step process is to use non-flowing glue PP to press and stack the layers in the step part. And our product needs to achieve a high-speed effect, so the whole board uses Panasonic M6 PCB high-speed board, but there is no non-flowing glue PP corresponding to M6 on the market. We can only use flowing glue PP for pressing, which is very challenging for the production of step parts.

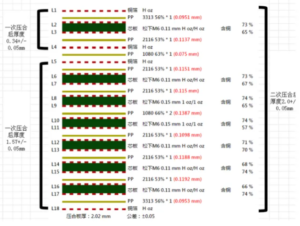

In addition, this product is also an 18-layer mechanical blind hole board. Let’s take a look at the pressing structure diagram

The motherboard of the product is divided into two boards, L1-4 and L5-18, and the finished product is made after three laminations. The lamination of multi-layer boards is extremely difficult, and the lamination of multi-layer special board products must be controlled in detail. The result of a mistake is that all the previous efforts are wasted!

Finally, in order to ensure the transmission of high-speed signals, reduce signal attenuation, ensure that the signal is stronger and more reliable, and also to prevent signal distortion problems, we also added back drilling technology in product production.

CKT-1 drills from the top layer to the bottom layer with a depth of 1.25+/-0.05, CKB-1 drills from the bottom layer to the top layer with a depth of 0.35mm and a depth of 1.45+/-0.05, 0.351mm with a depth of 1.25+/-0.05, 0.352mm with a depth of 1.05+/-0.05, and 0.353mm with a depth of 0.2+/-0.05.