12-layer Rigid-Flex HDI PCB

The development of PCB can be traced back to the 1950s, when it started with the quantitative production of some single-sided and double-sided PCBs. In the 1970s, multi-layer PCBs developed rapidly, and continued to move towards high precision, high density, and high reliability. This also laid the foundation for the rigid-flex board. In the birth and continuous development of FPC and PCB, a new product, the rigid-flex board, was born. It can be said that the rigid-flex board is the youngest member of the PCB family.

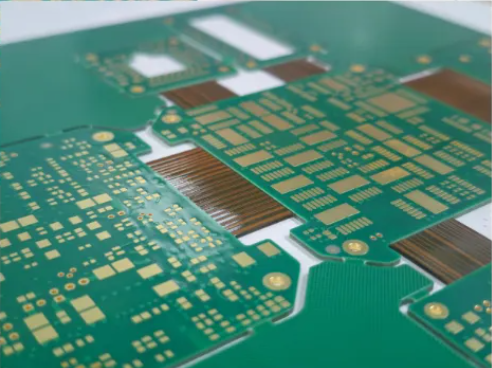

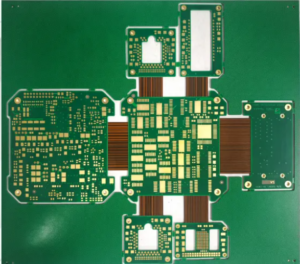

Early Rigid-Flex PCBs were mainly used in military and aerospace fields that have extremely high requirements for reliability and performance, such as aircraft, missiles and other high-end equipment. Today SHENZHEN BEST PCBA CO.,LIMITED bring you a 12-layer HDI Rigid-Flex PCB, let’s take a look at it first!

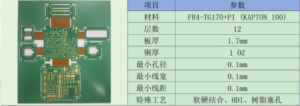

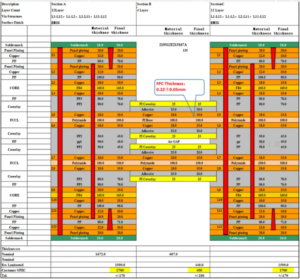

Rigid-flex boards can be said to be a beautiful work of art in PCB products! In the same level of rigid-flex boards, a variety of different stacking structures can be produced. For example, a 12-layer rigid-flex board can be a 10-layer rigid board + 2-layer flex board structure, or an 8-layer rigid board + 4-layer flex board structure, or a 6-layer rigid board + 6-layer flex board structure. The layer settings of soft and hard boards are not fixed, and can be set by engineers according to their needs! The internal structure of our 12-layer rigid-flex board is 8-layer rigid board + 4-layer flex board. Let’s appreciate its stacking structure:

L5-6, L7-8 are four-layer flex boards, and the other layers are FR4 rigid boards. In addition, this product is a 1 step blind and buried HDI. In order to ensure the stability and reliability of the product, we use plugged with resin technology to fill the buried hole part, and the blind hole part is filled with electroplating.

Of course, this product is not used in general electronic equipment. It is a PCB for industrial control equipment!

We delivered the product perfectly to our customers!